Strengthen the prevention and control capabilities of power safety accidents

Release time:

2025-06-06

On the basis of maintaining the safe operation and correct operation of power equipment, more attention should be paid to the quality of the equipment and materials used for power transmission, especially in the summer. Electricity is not like other dangerous things, it cannot be seen or touched. However, once negligent, it often costs a huge price of life, and even can be called an electric tiger. In fact, electricity itself is more terrifying than a tiger. Cable aging is a significant safety hazard, and many fires caused by electricity are often caused by cable aging. Therefore, it is necessary to regularly check whether cables are aging. However, it still requires certain technical skills to check whether wires are aging. Our common cables rely on a layer of outer sheath for insulation. However, over time, if the cable is oxidized or corroded in the air, the insulation performance of the cable will become lower and lower. Eventually, it will age and become hard or even fall off. When the cable ages to this level, it basically has no insulation ability, and once the insulation performance is reduced to a certain extent, During use, it is easy to be broken down, leading to accidents such as fires and electric shock to employees. Understanding the basic knowledge of judging cable aging can eliminate safety hazards. Here are a few methods and experiences for judging cable aging: The first way to view the appearance of the cable is to observe the insulation layer of the cable. If the cable is found to be hard, with cracks on the outer layer, color fading, darkening, or even detachment, it indicates that the aging problem of the cable is already serious. It is best to replace it in a timely manner to avoid danger. The second method is a more professional and accurate one, which is to use an insulation resistance meter to measure the insulation of electrical circuits. The insulation of different circuits has different allowable values. For example, for household 220V lines in use, the insulation resistance cannot be less than 0.22 megaohms; The wet value on rainy days should not be less than 0.1 megaohms. If the measured insulation resistance value is less than the above value, it indicates that there is a problem with the insulation of the electrical circuit. Of course, the lifespan of cables varies depending on their usage.

On the basis of maintaining the safe operation and correct operation of power equipment, more attention should be paid to the quality of the equipment and materials used for power transmission, especially in the summer. Electricity is not like other dangerous things, it cannot be seen or touched. However, once negligent, it often costs a huge price of life, and even can be called an electric tiger. In fact, electricity itself is more terrifying than a tiger.

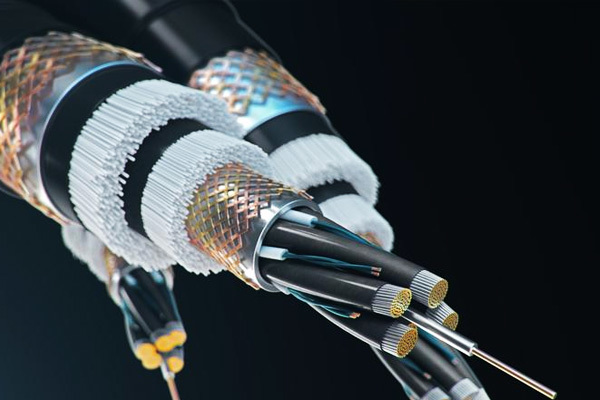

Cable aging is a significant safety hazard, and many fires caused by electricity are often caused by cable aging. Therefore, it is necessary to regularly check whether cables are aging. However, it still requires certain technical skills to check whether wires are aging. Our common cables rely on a layer of outer sheath for insulation. However, over time, if the cable is oxidized or corroded in the air, the insulation performance of the cable will become lower and lower. Eventually, it will age and become hard or even fall off. When the cable ages to this level, it basically has no insulation ability, and once the insulation performance is reduced to a certain extent, During use, it is easy to be broken down, leading to accidents such as fires and electric shock to employees. Understanding the basic knowledge of judging cable aging can eliminate safety hazards. Here are a few methods and experiences for judging cable aging:

The first way to view the appearance of the cable is to observe the insulation layer of the cable. If the cable is found to be hard, with cracks on the outer layer, color fading, darkening, or even detachment, it indicates that the aging problem of the cable is already serious. It is best to replace it in a timely manner to avoid danger.

The second method is a more professional and accurate one, which is to use an insulation resistance meter to measure the insulation of electrical circuits. The insulation of different circuits has different allowable values. For example, for household 220V lines in use, the insulation resistance cannot be less than 0.22 megaohms; The wet value on rainy days should not be less than 0.1 megaohms. If the measured insulation resistance value is less than the above value, it indicates that there is a problem with the insulation of the electrical circuit. Of course, the lifespan of cables varies depending on their usage.

Recent information

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible

Contact Us

Tel: +86-519-88804400

Mobile: +86-13337881658

E-mail: hbwong@mosstee.com

Address:#8, Hongzhuang Industrial Zone, Yaoguan Town, Jingkai District, Changzhou, 213011 Jiangsu, China

Copyright © 2025 Mosstee (Changzhou) Technology Co., Ltd.