Enhancing EV Battery Management Systems with CuSn0.3 Alloy Wire

Release time:

2025-06-17

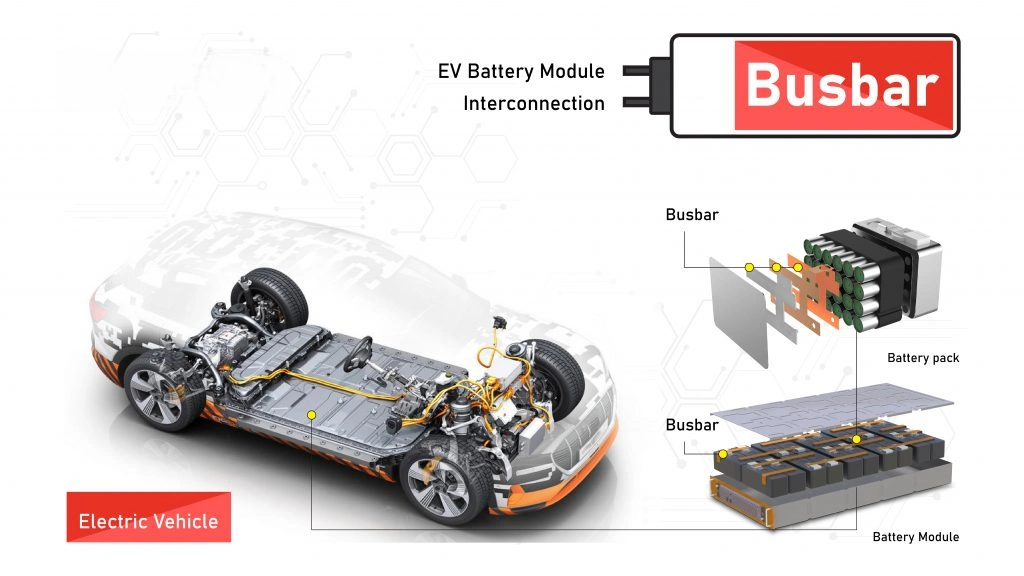

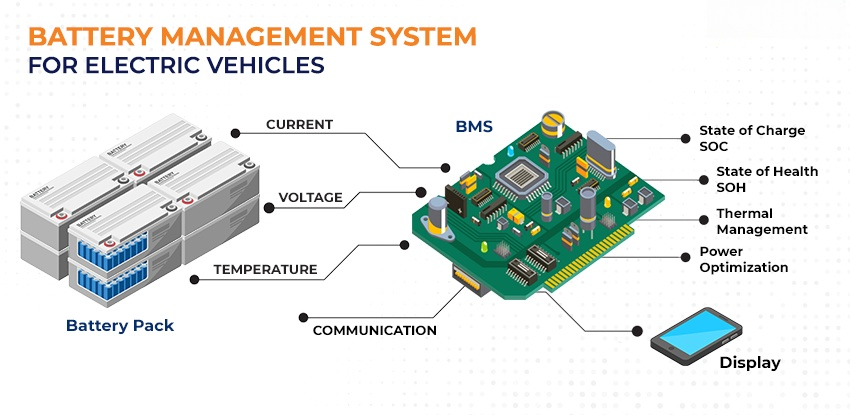

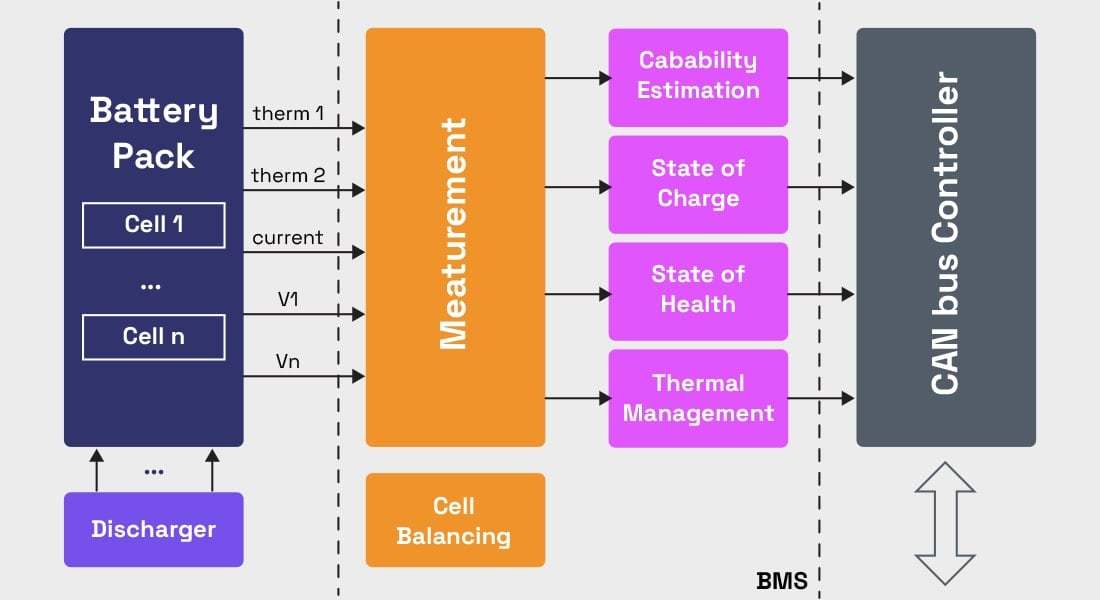

As electric vehicles (EVs) continue to evolve, the performance and reliability of their Battery Management Systems (BMS) become increasingly critical. These systems are responsible for monitoring and managing key parameters like voltage, current, and temperature across individual battery cells, ensuring safety, efficiency, and extended battery life. A vital, yet often overlooked, element of the BMS is the conductor wire that enables real-time data transmission and energy balancing. Among the many material options, CuSn0.3 alloy wire (UNS C18835) stands out for its unique balance of electrical and mechanical properties.

As electric vehicles (EVs) continue to evolve, the performance and reliability of their Battery Management Systems (BMS) become increasingly critical. These systems are responsible for monitoring and managing key parameters like voltage, current, and temperature across individual battery cells, ensuring safety, efficiency, and extended battery life. A vital, yet often overlooked, element of the BMS is the conductor wire that enables real-time data transmission and energy balancing. Among the many material options, CuSn0.3 alloy wire (UNS C18835) stands out for its unique balance of electrical and mechanical properties.

Why Conductive Materials Matter in BMS Applications

The BMS requires highly reliable signal and power transmission lines to function correctly. Materials used in these connections must demonstrate:

Stable conductivity for accurate voltage sensing

Excellent fatigue resistance to withstand vibrations and thermal cycling

Corrosion resistance for long-term environmental stability

Strong mechanical strength to avoid deformation in high-density routing

This makes high-performance copper alloys essential in EV BMS wiring.

CuSn0.3 (C18835): A Copper-Tin Alloy Built for Reliability

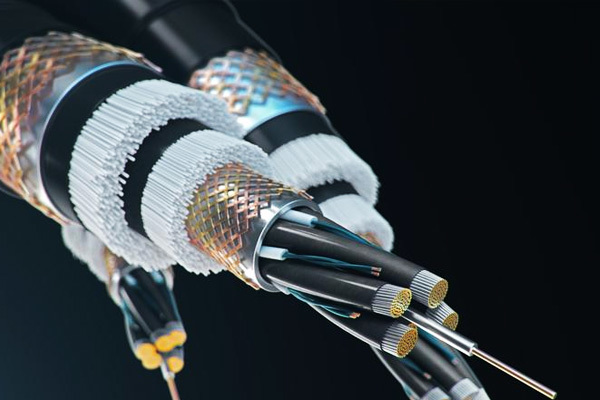

CuSn0.3 is a low-alloyed copper material containing approximately 0.25% tin (Sn) and oxygen content below 5 ppm. Developed for high-reliability applications, it combines several advantages:

Electrical conductivity: 77–80% IACS

Tensile strength: 520–540 MPa

Corrosion resistance: Excellent, suitable for harsh automotive environments

Weldability and formability: High, enabling stable connections and complex harness routing

Flex life: Superior, supporting frequent bending and vibration without fatigue failure

These properties make CuSn0.3 particularly suitable for signal cables, voltage monitoring wires, and connector pins in BMS modules.

Lamifil’s CuSn0.3 (UNS C18835) alloy wire has proven its effectiveness in automotive signal conductors and high-precision interconnects where long-term stability is a must.

Application Example: Signal Wires in Cell Monitoring Units

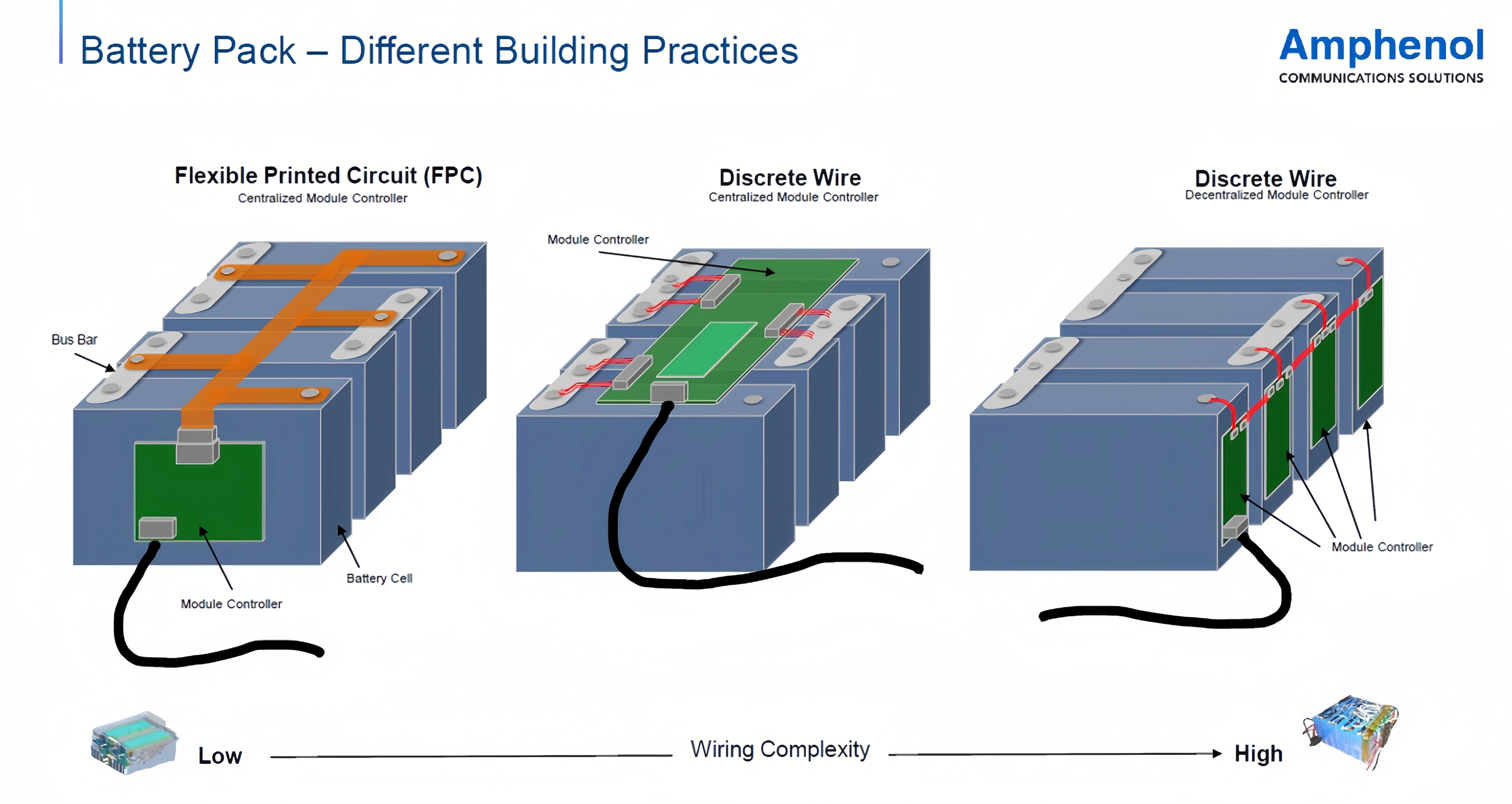

In a typical BMS layout, individual lithium-ion cells are grouped into modules. Each module uses cell monitoring units (CMUs) to measure voltages and temperatures. The signal lines connecting these CMUs to the main controller must be ultra-reliable, compact, and fatigue-resistant. CuSn0.3 wire, with its combination of high strength and good conductivity, is an ideal fit for these connections—better than pure copper in many use cases, especially where space is limited and mechanical stress is high.

Future Trends and Material Optimization

As the EV industry pushes toward higher voltage platforms (800V+), fast charging, and modular battery designs, the requirements for BMS wiring continue to grow. Alloy wires like CuSn0.3 not only meet today’s needs but also offer long-term material consistency and manufacturability for scalable EV production.

Conclusion

The copper-tin alloy CuSn0.3 (C18835) offers a robust solution for the wiring challenges in modern BMS applications. Its proven performance in signal integrity, fatigue resistance, and corrosion protection makes it a preferred material for automotive engineers and wire harness designers alike. At Mosstee, we provide a range of high-performance alloy wires tailored to the needs of the evolving EV industry—including CuSn series wires ready for integration into your next-generation BMS systems.

Recent information

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible

Contact Us

Tel: +86-519-88804400

Mobile: +86-13337881658

E-mail: hbwong@mosstee.com

Address:#8, Hongzhuang Industrial Zone, Yaoguan Town, Jingkai District, Changzhou, 213011 Jiangsu, China

Copyright © 2025 Mosstee (Changzhou) Technology Co., Ltd.