Ultra-Fine 0.025 mm Pure Nickel Wire: Key Material for Micro-Welding and High-Reliability Electronics

Release time:

2025-06-17

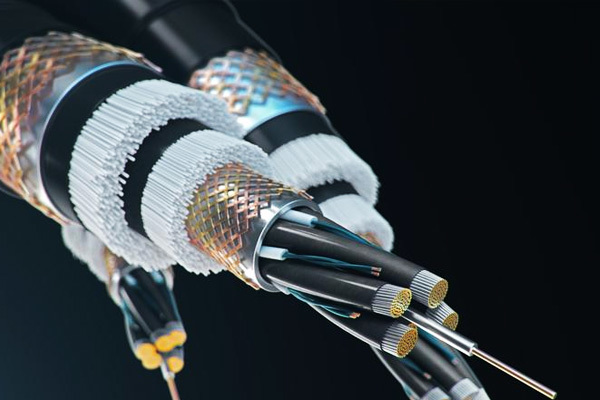

As electronics continue to miniaturize, the demand for ultra-fine, high-purity conductive materials has surged. One such material at the forefront of this shift is 0.025 mm pure nickel wire, widely used in battery tab welding, sensors, and microelectronic packaging. With outstanding weldability, chemical resistance, and mechanical stability, ultra-fine nickel wire offers the performance required in today’s most demanding micro-assembly environments.

As electronics continue to miniaturize, the demand for ultra-fine, high-purity conductive materials has surged. One such material at the forefront of this shift is 0.025 mm pure nickel wire, widely used in battery tab welding, sensors, and microelectronic packaging. With outstanding weldability, chemical resistance, and mechanical stability, ultra-fine nickel wire offers the performance required in today’s most demanding micro-assembly environments.

Purity, Precision, and Performance

NP1-grade pure nickel wire (commonly equivalent to Nickel 200 / UNS N02200) contains ≥99.6% nickel, with very low levels of carbon, sulfur, and other impurities. Its ultra-fine 0.025 mm diameter makes it suitable for micro spot welding and signal-level electrical connections.

Key properties include:

Electrical resistivity: ~6.99 µΩ·cm

Melting point: ~1453°C

Excellent resistance to alkaline and neutral environments

Non-magnetic (in annealed state)

Stable performance under thermal cycling

These attributes make it ideal for long-term, high-reliability use in harsh environments and compact form factors.

Reference: Nickel 200/201 Technical Datasheet by NeoNickel (PDF)

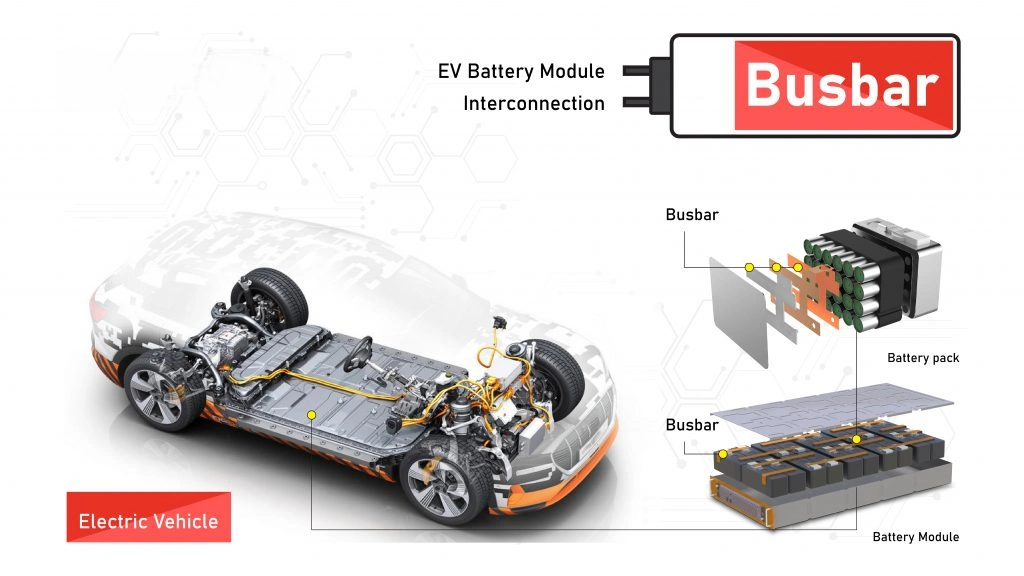

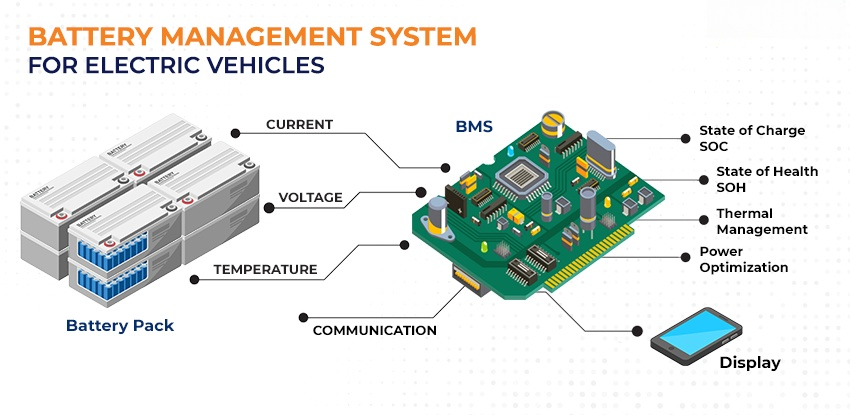

Application 1: Coin Cell Battery Tab Welding

In lithium coin cell production (e.g., CR2032, LR44), nickel wire is commonly used for connecting tabs to electrodes through resistance or ultrasonic welding. The wire's small diameter allows precise energy control, minimizing heat damage during joining.

Reference: Panasonic Coin-Type Lithium Battery Handbook (archived PDF link)

Application 2: Sensor Lead Wires

Sensors used in chemical, medical, and environmental monitoring rely on corrosion-resistant, non-reactive conductors. 0.025 mm nickel wire is often used to route analog or low-current signals due to its dimensional stability and oxidation resistance.

Reference: MDPI Sensors Journal - Thin Film Packaging Materials (2022)

Application 3: Microelectronic and MEMS Packaging

Micro-Electro-Mechanical Systems (MEMS), semiconductor devices, and hybrid circuits increasingly require fine wire bonding under tight geometric constraints. Nickel wire provides an alternative to gold or aluminum where cost, corrosion resistance, and mechanical strength are priorities.

Reference: IEEE/IMAPS Proceedings - Alternative Wire Materials in Microbonding (2021)

Why Not Nickel-Plated Alternatives?

Although nickel-plated copper or steel wires are common in cost-sensitive applications, they cannot match the uniformity and corrosion performance of solid nickel wire, especially at ultra-fine diameters. For applications where long-term performance and chemical stability are non-negotiable, solid pure nickel remains the industry standard.

Product Availability and Quality Control

At Mosstee, we offer NP1-grade nickel wire in diameters down to 0.025 mm, produced via controlled drawing and annealing processes. Our products are:

Supplied on micro spools or cut lengths

Surface-cleaned and burr-free for welding applications

Subject to strict dimensional and purity inspections

Traceable with mill certificates available upon request

Specifications available upon request. Contact us.

Conclusion

Whether in battery welding, sensor leads, or micro-packaging, 0.025 mm pure nickel wire provides unmatched precision, stability, and long-term reliability. As industries move toward smaller, smarter, and more durable electronic systems, this ultra-fine material continues to be a key enabler of next-generation designs.

Recent information

*Attention: Please ensure accurate information filling and maintain smooth communication. We will contact you as soon as possible

Contact Us

Tel: +86-519-88804400

Mobile: +86-13337881658

E-mail: hbwong@mosstee.com

Address:#8, Hongzhuang Industrial Zone, Yaoguan Town, Jingkai District, Changzhou, 213011 Jiangsu, China

Copyright © 2025 Mosstee (Changzhou) Technology Co., Ltd.