Product Description

Description:

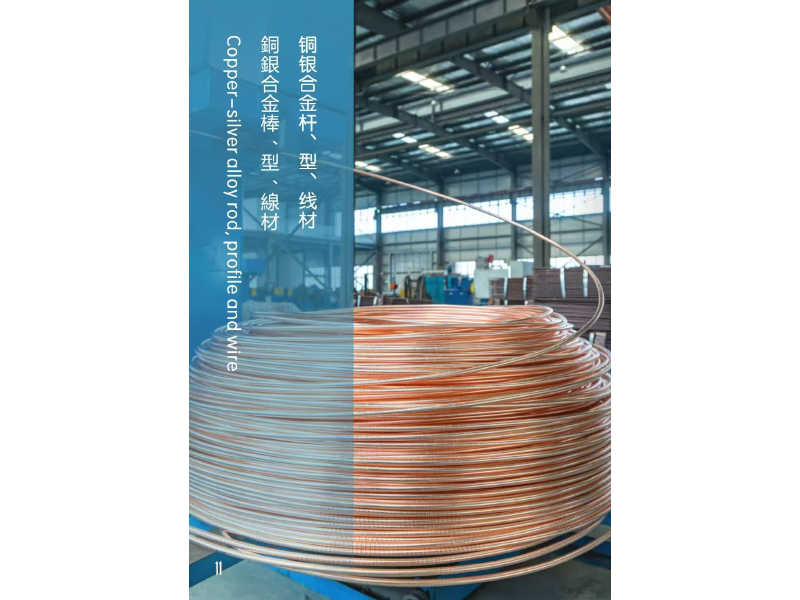

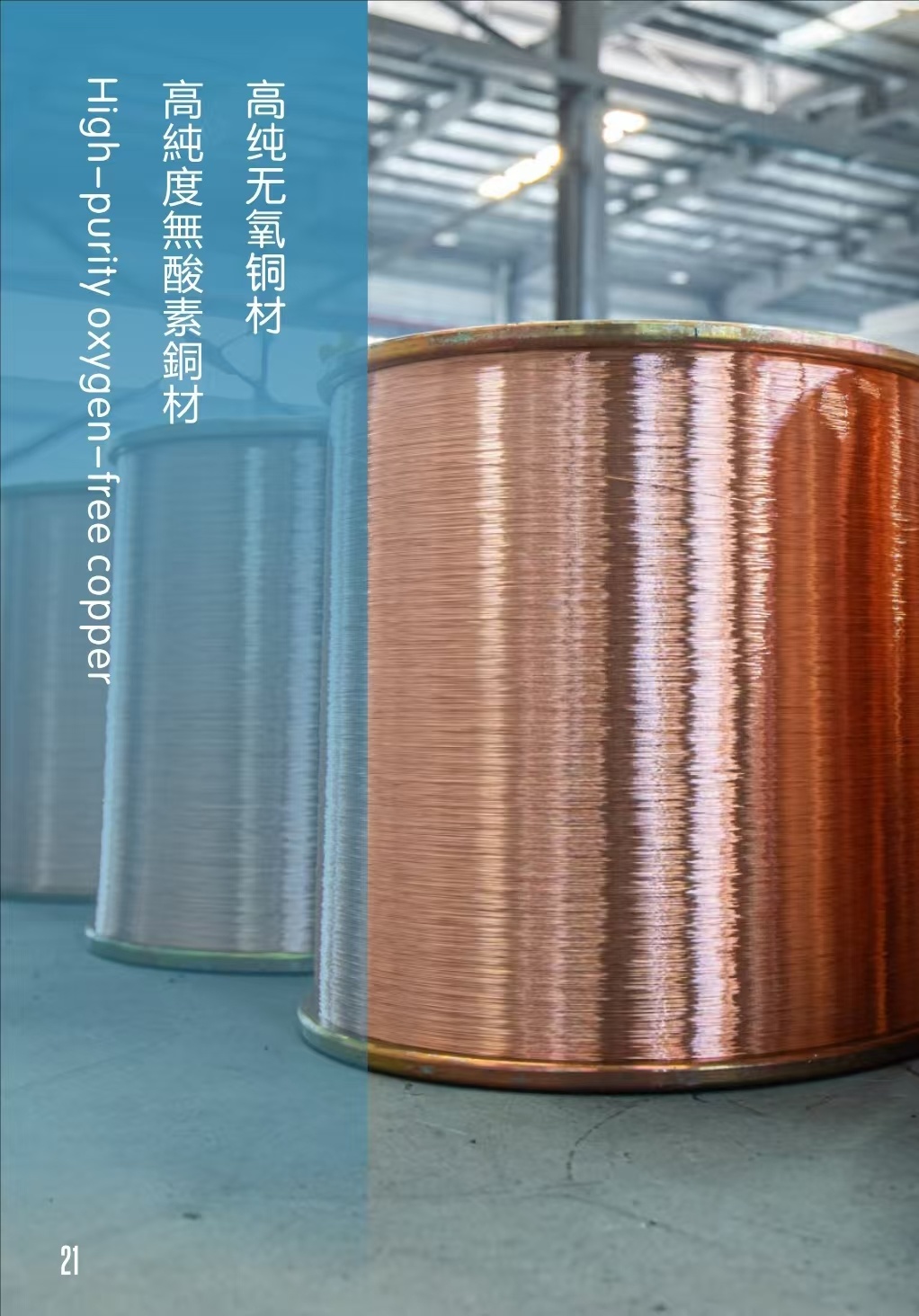

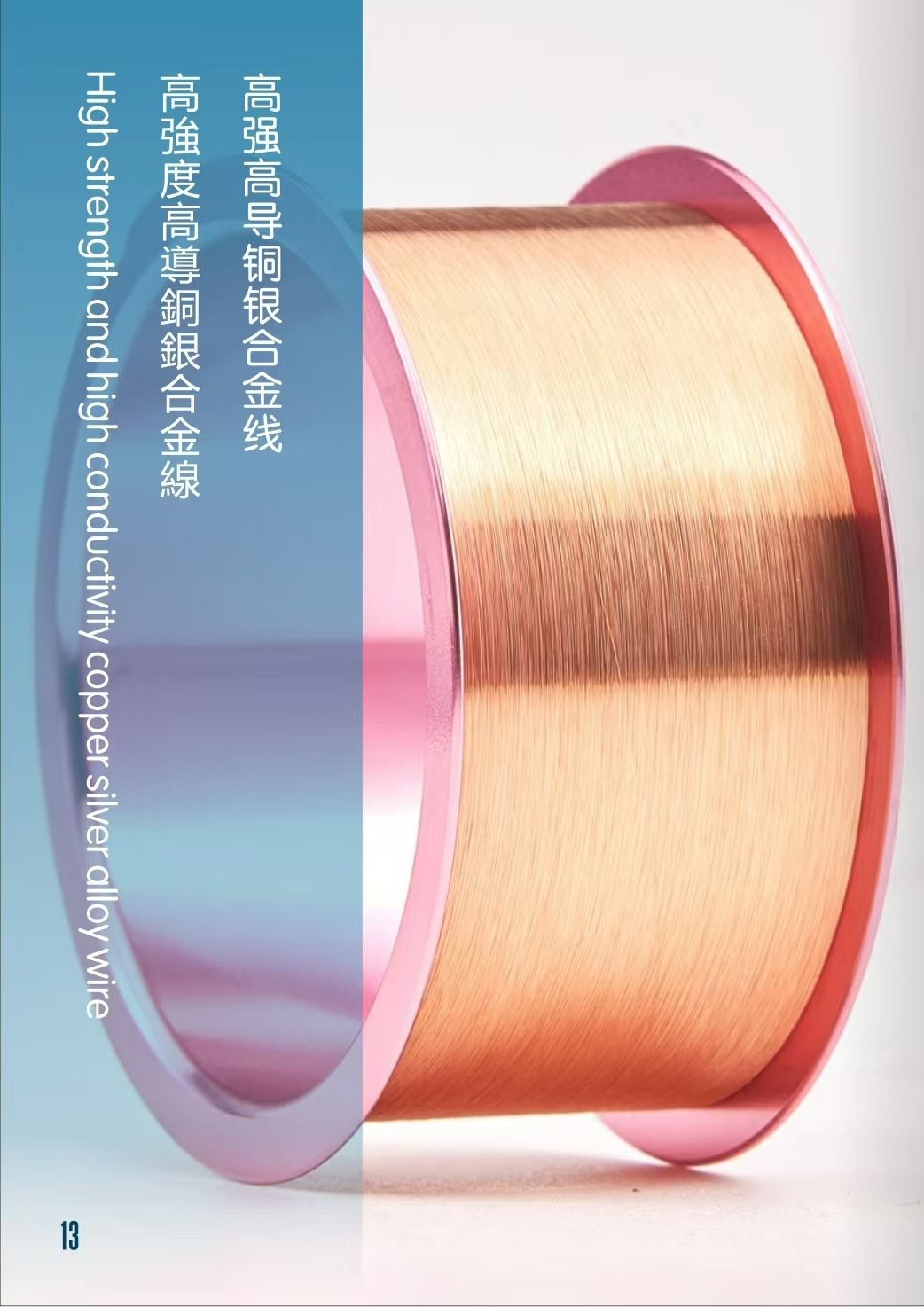

Copper Alloy materials

Advantages:

– high electrical and thermal conductivity

– outstanding corrosion resistance

– good forming and processing properties

– excellent suitability for surface coating

Products type:

– Copper alloy wire & conductor

– Copper busbar

Technical Parameters

|

CDA Alloy No. |

C10100 |

C10200 |

C11000 |

C15000 |

C17200 |

C26000 |

C51000 |

|

Alloy Name |

Certified |

OFHC |

ETP |

Zirconium |

Beryllium |

Cartridge |

Phosphor |

|

Chemical Composition (%) |

99.99 Cu (Min.) |

99.95 Cu (Min.) |

99.90 Cu (Min.) .04 O |

98.95 Cu .15 Zr |

98.1 Cu 1.9 Be |

70 Cu 30 Zn |

94.8 Cu 5.0 Sn 2 P |

|

Density (lbs./in.³) |

0.323 |

0.323 |

0.323 |

0.321 |

0.298 |

0.308 |

0.32 |

|

Electrical Conductivity (% IACS @ 68°F ) |

101 |

102 |

100 |

93 |

22 |

28 |

15 |

|

Resistivity (Ω/circ. mil/ft) |

10.3 |

10.3 |

10.3 |

11.2 |

46.2 |

37 |

69.1 |

|

Approximate Melting Point (°F) |

1981 |

1981 |

1981 |

1796 |

1590 |

1680 |

1750 |

|

Tensile Strength Hard Temper (kpsi) |

55 |

55 |

55 |

64 |

152 |

109 |

110 |

|

Tensile Strength Soft Temper (kpsi) |

34 |

34 |

34 |

30 |

68 |

52 |

51 |

|

Yield Strength Hard Temper (kpsi) |

50 |

50 |

50 |

62 |

125 |

68 |

85 |

|

Yeild Strength Soft Temper (kpsi) |

11 |

11 |

12 |

13 |

28 |

21 |

21 |

|

Elongation Hard Temper (%) |

6 |

6 |

5 |

1.5 |

1 |

5 |

5 |

|

Elongation Soft Temper (%) |

36 |

36 |

36 |

30 |

42 |

30 |

49 |

|

Material group |

Material |

EN |

UNS |

|

High copper alloys |

CuSn0.15 |

CW117C |

C14415 |

|

CuSn0.3 |

|

C14425 |

|

|

CuAg0.10P |

CW016A |

C11600 |

|

|

CuNi3SiMg |

CW112C |

C70250 |

|

|

CuCr1Zr |

CW106C |

C18150 |

|

|

CuFe2P |

CW107C |

C19400 |

|

|

CuCrAgFeTiSi |

|

C18080 |

|

|

CuMg0.1 |

|

C15500 |

|

|

CuMg0.2 |

CW127C |

|

|

|

Bronze |

CuSn4 |

CW450K |

C51100 |

|

CuSn5 |

CW451K |

C51000 |

|

|

CuSn6 |

CW452K |

C51900 |

|

|

CuSn8 |

CW453K |

C52100 |

|

|

Brass |

CuZn15 |

CW502L |

C23000 |

|

CuZn30 |

CW505L |

C26000 |

|

|

CuZn36 |

CW507L |

C26800 C27000 |

|

|

CuZn37 |

CW508L |

C27000 C27200 C27400 |

|

|

Nickel silver |

CuNi12Zn24 |

CW403L |

C75700 |

|

CuNi18Zn20 |

CW409L |

C76400 |

|

Material Group |

Material |

Diameter |

Density |

Resistivity |

IACS |

UTS |

|

mm |

g/cm3 |

μΩ.cm |

% |

MPa |

||

|

Copper |

CuHc |

0.03-2.40 |

8.86 |

1.724 |

100 |

240 |

|

CuHc 27% Nickel Plated |

0.08-2.40 |

8.82 |

2.205 |

78 |

300 |

|

|

CuOFHC |

0.03-2.40 |

8.86 |

1.724 |

100 |

240 |

|

|

CuOFHC 27% Nickel Plated |

0.08-2.40 |

8.82 |

2.205 |

78 |

300 |

|

|

Green6 |

0.05-1.20 |

8.88 |

1.997 |

85 |

380 |

|

|

Green6 27% Nickel Plated |

0.08-1.20 |

8.87 |

2.670 |

65 |

400 |

|

|

Green8 |

0.06-0.90 |

8.94 |

1.898 |

90 |

440 |

|

|

CuP |

0.06-1.85 |

8.93 |

1.784 |

96 |

240 |

|

|

White Metal |

0.08-0.90 |

8.92 |

9.892 |

17 |

250 |

|

|

CuNiSi |

0.08-0.90 |

8.87 |

4.041 |

42 |

640 |

|

|

Brass 80/20 |

0.08-0.90 |

8.62 |

5.301 |

32 |

450 |

|

|

Bronze6 |

0.06-0.80 |

8.84 |

13.770 |

12 |

540 |

|

|

Silver |

Ag990 |

0.07-2.00 |

10.48 |

1.730 |

99 |

230 |

|

Ag935 |

0.07-0.90 |

10.15 |

2.000 |

86 |

350 |

|

|

Nickel |

Pure Nickel |

0.06-1.50 |

8.64 |

7.804 |

22 |

410 |

Related Products

Product inquiry

Contact Us

Tel: +86-519-88804400

Mobile: +86-13337881658

E-mail: hbwong@mosstee.com

Address: #8, Hongzhuang Industrial Zone, Yaoguan Town,

Jingkai District, Changzhou, 213011 Jiangsu, China

Contact us

Copyright © 2023 Mosstee (Changzhou) Technology Co., Ltd.